Home > Products > Aluminum Profile > Aluminum/Aluminum Folding Doors and Windows for Shop and Home and Hotel

Aluminum/Aluminum Folding Doors and Windows for Shop and Home and Hotel

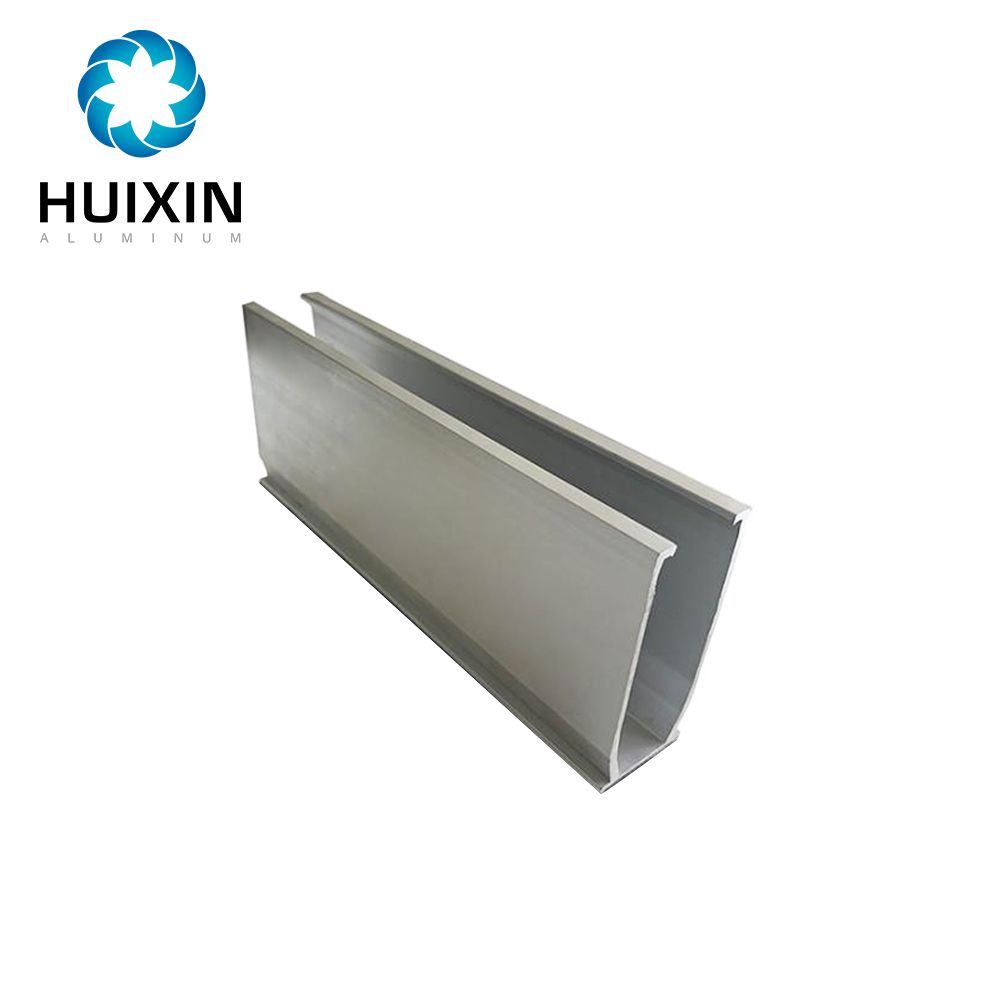

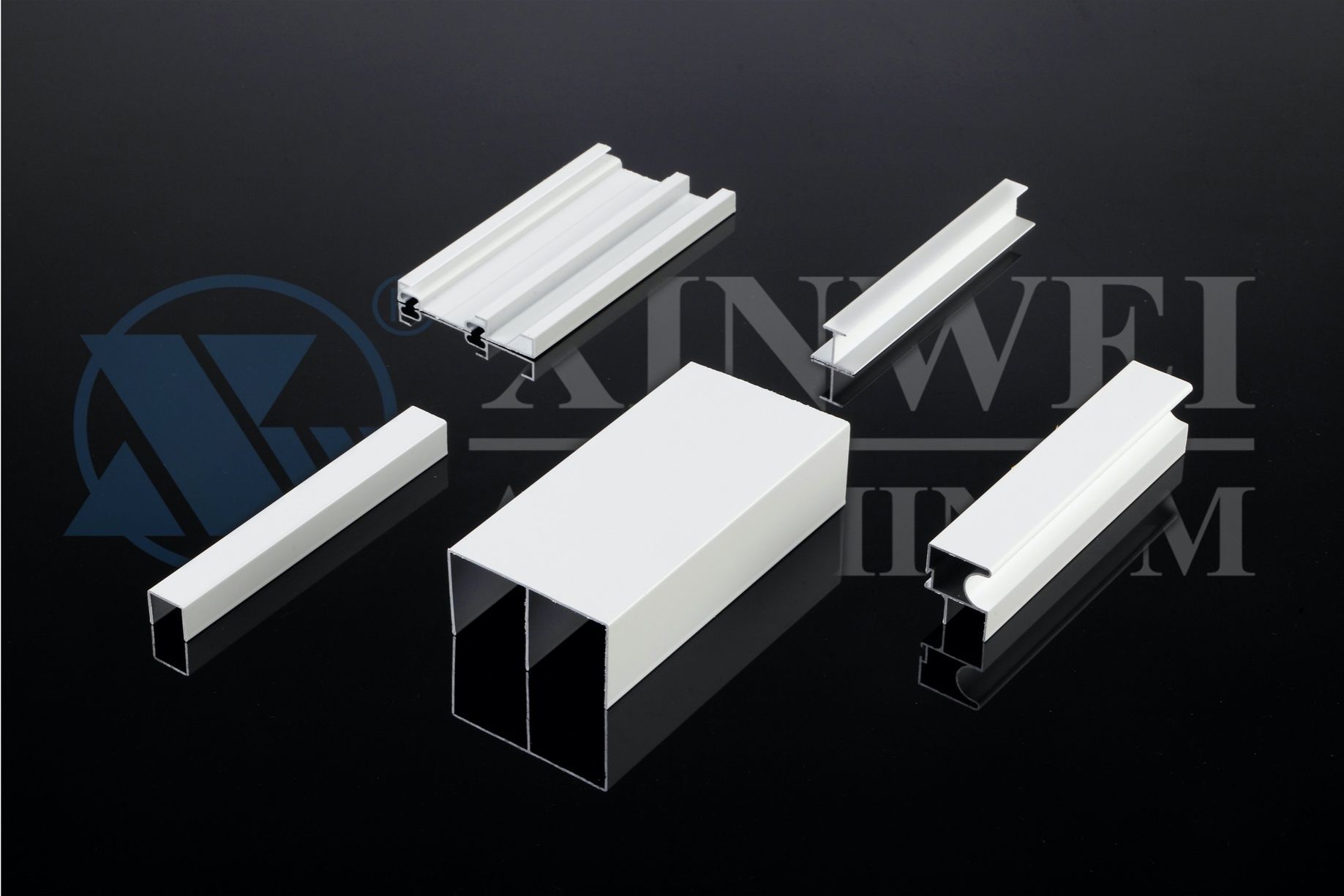

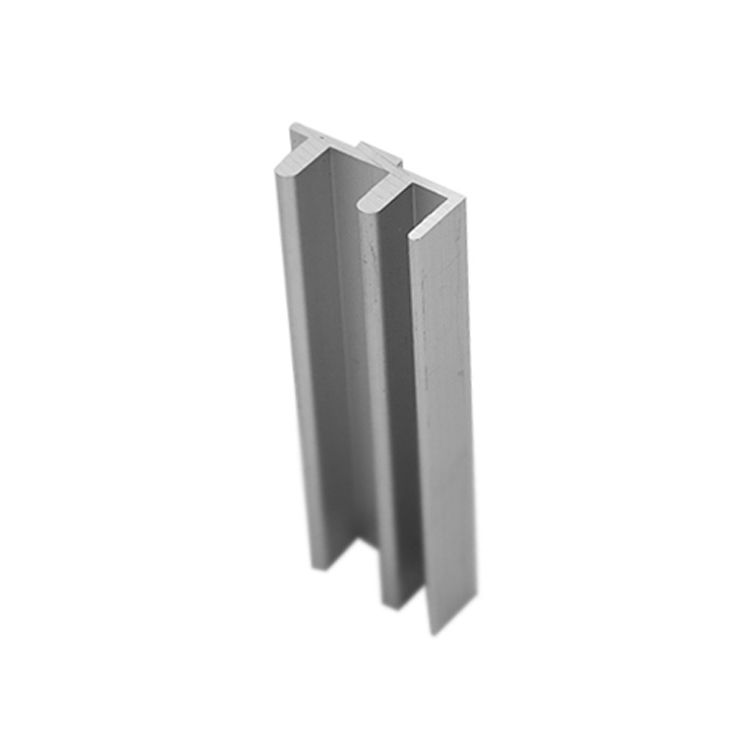

Aluminum/Aluminium Doors and Windows With AAMA and AS2047(1).Product: aluminium profile(2).20 years warranty.(3).High corrosion resistance.(4).5-10 years weather resistance.(5).Good wear resistance & anti-scratch.(6).Size customized.More Information:1.Material: Aluminium alloy 6063, 6061.2.Tempe......

Send Inquiry

Product Description

Aluminum/Aluminium Doors and Windows With AAMA and AS2047

(1).Product: aluminium profile

(2).20 years warranty.

(3).High corrosion resistance.

(4).5-10 years weather resistance.

(5).Good wear resistance & anti-scratch.

(6).Size customized.

More Information:

1.Material: Aluminium alloy 6063, 6061.

2.Temper: T5, T6.

3.Quality standard: DIN; AAMA; AS/NZS; CHINAGB.

4.Surface treatment: Mill finish, anodized, powder coated, wood grain, polished, brushed, electrophoresis, etc.

5.Color avalilable: Anyone is available based on your color samples.

6.Packing details: Shrinking film; Plastic & kraft paper; Wooden pallet

Carton packing; By customer's requirements.

7.Samples Time: Normally, 2-3 weeks.

8.Delivery: 25-30 days for mass production.

9.Production Capacity: 6000MT/Month

10.MOQ: It's based on the drawings. Basically, it's 2 tons.

11.Port: Shanghai; Guangzhou; As per requested.

What We Can Do

Our Advantages!

1. 22 years' experiences of manufacturing, 12 years' exporting experiences as ALIBABA GOLDEN SUPPLIER.

2. STRONG R&D: Help customers finalize the design, strong tool design ability,excellent pressing and surface treament technology.

3.Strict quality management: ISO Administration system.

4. 24 hours on-line communication.Professional, Patient, Flexible.

5. High capacity of manufaturing and wide range of products.

6. Be able to provide secondary fabricating.

7. Small order isaccepted.

8. Be able to provide one-stop supply solution.

9. Multiple payment methods: TT, LC. DP,OA.

FAQ to Save Your Precious Time!

Q1: What's the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10 um. Yes, we can do 15um and above.

Q2: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

Q3: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q4: How's the weather resistance for wood grain finish D1010?

A: (1). Powder: Akzo Noble Interpon D1010.

(2). Wood grain film: Italian Menphis.

(3). Standard complied: American AAMA Standard.2603

(4). UV test:1000 hours.

(5). Salt spraying test:1000 hours.

(6). Normal weather: 10 years color guarantee.

Q5: What's the payment terms?

A: Usually by T/T, 30% deposit and the balance paid before shipment.

Q6: What certification do you have? What's your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q7: What's the delivery time for samples and mass production?

A: (1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Q8: What's the packing way?

A: Commonly we use plastic film and kraft paper, also we can make as per customers' requirements.

(1).Product: aluminium profile

(2).20 years warranty.

(3).High corrosion resistance.

(4).5-10 years weather resistance.

(5).Good wear resistance & anti-scratch.

(6).Size customized.

More Information:

1.Material: Aluminium alloy 6063, 6061.

2.Temper: T5, T6.

3.Quality standard: DIN; AAMA; AS/NZS; CHINAGB.

4.Surface treatment: Mill finish, anodized, powder coated, wood grain, polished, brushed, electrophoresis, etc.

5.Color avalilable: Anyone is available based on your color samples.

6.Packing details: Shrinking film; Plastic & kraft paper; Wooden pallet

Carton packing; By customer's requirements.

7.Samples Time: Normally, 2-3 weeks.

8.Delivery: 25-30 days for mass production.

9.Production Capacity: 6000MT/Month

10.MOQ: It's based on the drawings. Basically, it's 2 tons.

11.Port: Shanghai; Guangzhou; As per requested.

What We Can Do

Alloy: | 6063 | 6061 | 6060 | 6005 | 6082 | 6463 | 7075 |

| Temper : | T5 | T6 | T4 | ||||

| Standard: | DIN | AAMA | AS | CHINAGB | |||

| Certification: | ISO9001: 2008. | ||||||

| Surface Finish: | Mill finish | Anodizing | Powder Coating | Wood Grain | Electrophoresis | Polished | Brushed |

| Color: | Anodizing: | Silver, bronze, champagne, titanium, nickel, golden yellow, etc. | |||||

| Anodizing thickness is up to 25um. | |||||||

| Powder Coating: | White, black, bronze, grey, green, etc . | ||||||

| Powder coating thickness is more than 60um. | |||||||

| Wood Grain: | 1. Italian MENPHIS transfer printing paper. | ||||||

| 2. AKZO NOBEL INTERPON D1010(10 years warranty): Australia ceder, Bush cherry, Chest nut, Jarrah I, Jarrah II, Western red ceder, etc. | |||||||

| 3. AKZO NOBEL INTERPON D34(5 years warranty): Bush wood, Western red, Jarrah, Snow gum, etc. | |||||||

| Electrophoresis: | Silver, nickel, golden yellow, black, champagne, etc | ||||||

| Polishing | Silver, nickel, golden yellow, black, etc | ||||||

| Brushing: | Silver, nickel, golden yellow, black, bronze, etc | ||||||

| Machining: | Cutting, punching, drilling, bending, weld, mill, CNC, etc. | ||||||

| OEM customized aluminium profiles are available. | |||||||

| TABLE OF CHEMICAL COMPOSITION OF ALUMINUM ALLOY | |||||||||||

Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | Impurity | Al | |

Unit | Total | ||||||||||

6063 | 0.2-0.6 | 0.45-0.9 | < 0.35 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.05 | < 0.15 | Surplus |

6061 | 0.4-0.8 | 0.8-1.2 | < 0.7 | 0.15-0.4 | < 0.15 | < 0.25 | 0.04-0.35 | < 0.15 | < 0.05 | < 0.15 | Surplus |

6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | ≤0.1 | ≤0.1 | ≤0.15 | ≤0.05 | < 0.1 | < 0.05 | < 0.15 | Surplus |

ADODIZINMG QUALITY | ||||

Grade | corrosion resistance | abrasive resistance | ||

CASS test | alkaline dropping test | sandtrial Abrasion coefficient f,g/um | ||

hours | grade | |||

AA10 | 16 | ≥ 9 | ≥ 50 | ≥ 300 |

AA15 | 32 | ≥ 9 | ≥ 75 | ≥ 300 |

AA20 | 56 | ≥ 9 | ≥ 100 | ≥ 300 |

AA25 | 72 | ≥ 9 | ≥ 125 | ≥ 300 |

| POWDER COATING QUALITY | ||||||||

| Gloss values | Thickness(um) | color variation | indentation resistance | adhesion | impact resistance | cupping test | presentation quality | |

| Max Thickness | Min Thickness | |||||||

| 60 | ≤ 120 | ≥ 40 | Color should be consistent with the sample color | ≥ 80 | 0 | No cracking and shedding phenomenon after the front impact test,small fine lines around the concave is allowed | No cracking and shedding phenomenon after the cupping test ( 6mm indentation depth ) | |

Our Advantages!

1. 22 years' experiences of manufacturing, 12 years' exporting experiences as ALIBABA GOLDEN SUPPLIER.

2. STRONG R&D: Help customers finalize the design, strong tool design ability,excellent pressing and surface treament technology.

3.Strict quality management: ISO Administration system.

4. 24 hours on-line communication.Professional, Patient, Flexible.

5. High capacity of manufaturing and wide range of products.

6. Be able to provide secondary fabricating.

7. Small order isaccepted.

8. Be able to provide one-stop supply solution.

9. Multiple payment methods: TT, LC. DP,OA.

FAQ to Save Your Precious Time!

Q1: What's the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10 um. Yes, we can do 15um and above.

Q2: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

Q3: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q4: How's the weather resistance for wood grain finish D1010?

A: (1). Powder: Akzo Noble Interpon D1010.

(2). Wood grain film: Italian Menphis.

(3). Standard complied: American AAMA Standard.2603

(4). UV test:1000 hours.

(5). Salt spraying test:1000 hours.

(6). Normal weather: 10 years color guarantee.

Q5: What's the payment terms?

A: Usually by T/T, 30% deposit and the balance paid before shipment.

Q6: What certification do you have? What's your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q7: What's the delivery time for samples and mass production?

A: (1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Q8: What's the packing way?

A: Commonly we use plastic film and kraft paper, also we can make as per customers' requirements.

Related Category

Wire Mesh

Pipe Fittings

Building Glass

Aluminum Profile

Plywood

Window

Ceiling

Mirror

Aluminum Composite Panel

Wallpaper

Fireplace, Stove & Parts

Composite Pipe & Tube

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.